Fall Protection at the Top of the Quarry Face

Regulation 9 of the Safety, Health and Welfare at Work (Quarries) Regulations 2008 requires the operator to ensure, as regards that quarry, that work is planned taking into account the elements of the safety statement that concern the risks of falls. Therefore the Operator needs to consider any activities that take place at the top of quarry faces and this would include inadvertent and unauthorised access, face profiling and surveying activities, drilling operations and shotfiring operations.

Inadvertent and Unauthorised Access

It can be very difficult to prevent a determined intruder to the quarry, however the operator has a duty under regulation 34 of the Safety, Health and Welfare at Work (Quarries) Regulations 2008 to ensure that adequate precautions are taken to prevent unauthorised entry to the quarry including, where appropriate, the provision of barriers and that quarry boundaries are signposted and laid out so as to be clearly visible and identifiable. The operator must review the adequacy of boundaries and barriers designed to prevent unauthorised entry to the quarry and take appropriate action where there is evidence of unauthorised entry, in addition to this signage should indicate areas where there is a risk of falling or drowning

Face Profiling and Surveying of Quarry Faces

Where face profiling or surveying operations require a person to work at the top of a quarry face for any period of time then procedures must show how this is to be carried out safely. Although collective measures to prevent falls are preferable if access is occasional and only exposes an individual to the risk of falling then individual protection may be more appropriate. If the individual protection requires the use of a harness and a lanyard then

- The person should be trained in the safe use of the harness and lanyard.

- The lanyard must be adequately secured so that it can hold the weight of the person if they were to fall.

- The lanyard must not allow the person to reach the quarry face edge.

- The lanyard and harness must have a current certificate of thorough examination.

Drilling Operations

Where the face is to be drilled prior to blasting the

- operator must ensure that the driller is adequately protected from falling from the quarry face. Suitable procedures should generally have collective measures in place to prevent the driller from falling and where individual measures are necessary they should only be used for the purpose of erecting collective measures.

- If straps and poles are the collective system specified by the operator then the driller should ensure that short holes are drilled behind the last row of holes for the blast that will facilitate the erection of the straps and poles following the inspection of the blast. If the driller arrives on site and there is no collective system in place to prevent them from falling then the driller must wear a secured lanyard and harness where the lanyard must not allow the person to reach the quarry face edge, this should only be used to prepare for and for the erection of the collective system and not for the drilling of the shotholes.

Face Shothole Loading

- Loading and charging must only be carried out under the supervision of the Explosives Supervisor/Shotfirer.

- Collective systems must be used during loading operations.

Risk Assessment for Work at a Quarry Face

It is very important to carry out a site specific risk assessment including all the personnel likely to be involved in the blasting operation such as the Driller, Shotfirer, Explosives Supervisor, Quarry Manager, Bulk Explosive Supplier, and Geotechnical Consultant.

The following topics should be considered in any risk assessment

The site geology and stability of the face.

Access to the blast site for drill rig, delivery of stemming, explosives delivery vehicles, bulk explosive trucks and emergency vehicles.

Prevention of personnel and equipment from falling over the edge.

Traffic management during work at the top of the quarry face.

Blast design parameters such as spacing, burden, etc.

Profiling and surveying operations.

The weather conditions at the time when work is to be carried out.

The Work at Height hierarchy should be followed in selecting the method used:-

- Collective measures should be given priority over personal protective measures.

- Physical barriers such as the post and strap and safety bund should be considered first

- Only where the use of a physical barrier creates an unacceptable risk then other measures such as delineation of the danger zone or harnesses may be considered

- The Quarry operator should be able to show that they have considered how a fall from an open edge will be prevented for that particular blast.

Collective Systems

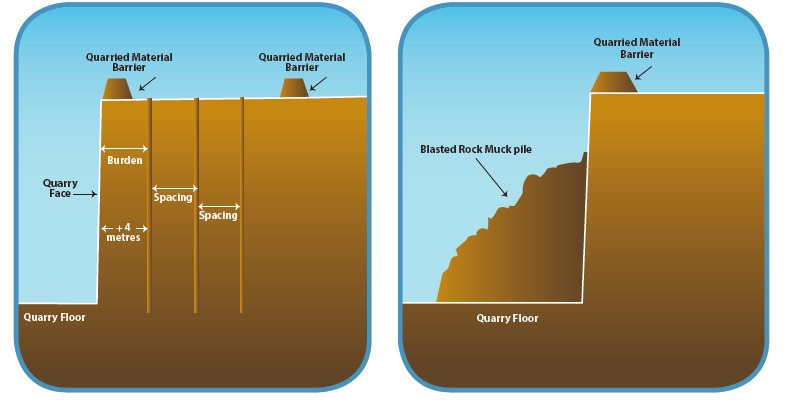

1. Use of quarried material to create a bunded barrier at the top of the face

This method is only suitable for use where the quarry face is well managed and the geology is consistently good and would be unsuitable where burdens are less than 4 metres, or where the rock is prone to back break and cracking and where the face often has overhanging rock. This system is best suited to lower face heights where burdens are in excess of 4 metres. The burdens could be extended by increasing the diameter of the shotholes however the vibration will need to be monitored if the maximum instantaneous charge is increased as a result of a greater shothole diameter. In order to build an adequate barrier at least 4 metres of free face is required between the quarry face edge and the planned first row of shotholes. If this is not available then the barrier is unlikely to be high or wide enough to prevent a person from falling and it can cause difficulty drilling the front row of shotholes as the quarried material in the barrier may flow into the shothole. The barrier must be at least 950mm above the quarry face edge at all points along its length and higher if vehicles are operating close to the face edge. The barrier must extend beyond either side of the planned front row of holes or where persons will be working and also at the sides if there is an exposed edge where a person could fall.

The quarried material in the barrier should be in place before drilling commences, this is best achieved by placing the quarried material behind the last row of holes of the planned blast so that when the blast is taken the next barrier is in place. Again this shows that the system is only suitable when faces are well managed and geology is

consistent. Putting an initial barrier made of quarried material at the quarry face edge places the vehicle operator at risk especially where the ground is shattered or there are slip planes. It is much safer to have the barrier installed

behind the next blast so that only maintenance of the barrier is necessary. The sequence is explained in the diagrams below.

When using bunded edge protection account must be taken of changes in elevation across the blast site to ensure an adequate barrier is in place

Drill Rig Operator working at a Quarry Face with fall protection provided by bunded edge protection made from quarried material | Quarry Workers marking out drill holes with fall protection provided by bunded edge protection made from quarried material |

|  |

2. Straps and Poles

This is an accepted method for providing fall protection at a quarry face. This system must be well managed to ensure it provides adequate protection when persons are working at the quarry face. The top strap must be at least 950 millimetres above the edge of the quarry face and the lower strap must not be more than 470 mm below the top strap. The straps must be adequately tensioned so that a person cannot fall through them. The top and lower strap should be connected by intermediate bands or other means to maintain a constant distance between the straps. If ropes are used instead of straps they must be adequately tensioned so that a person cannot fall through them and intermediate bands or other means to maintain a constant distance between the ropes must be used.

Strap and Pole Edge Protection Images

Strap and Pole system being erected and tensioned by a person using a harness with inertia reel lanyard

System of Work to be followed

Holes approximately 1 metre in depth and not more than 20 metres apart should have been predrilled for erecting the strap and pole system close to the face edge and in front of the planned first line of shotholes and also to the side if there is an exposed edge where a person could fall. If these are not pre-drilled the driller must drill these holes before commencing shothole drilling. When the driller alights the drill rig and approaches the quarry face the driller must wear a secured lanyard and harness where the lanyard must not allow the person to reach the quarry face. The harness and lanyard must be used by the driller until such time as the strap and pole system is in place. Care must be taken where there is shattered ground in the area to be drilled for the post holes.

- The strap and pole system must be erected by a person(s) who must wear a secured lanyard and harness where the lanyard must not allow the person to reach the quarry face edge.

- The strap and pole system must extend beyond either side of the planned front row of holes or where persons will be working and where a person could fall.

- The strap and pole system must be adequately tensioned and intermediate bands or other means to maintain a constant distance between the straps must be installed before the person(s) removes their lanyard and harness.

- The driller must only drill shotholes within the area of fall protection provided by the straps and poles.

- When completing the final row of holes the driller should drill holes to accommodate the poles for any future blast in that area.

- When loading the front row of holes at the face the straps and poles must be in front of the first row of shotholes at all points.

- Account must be taken of changes in elevation across the blast site to ensure an adequate barrier is in place throughout the working area.

- The straps and poles must remain in place until the front row of shotholes have been fully loaded and persons are no longer required to work in front of the first row of shotholes and have been instructed not to pass beyond the front row of shotholes.

- The straps and poles should only be removed by a person(s) wearing a secured lanyard and harness where the lanyard must not allow the person to reach the quarry face edge and not be removed where inclement weather or geological conditions such as shattered ground could place persons at risk during removal.

- The straps and poles must be removed to a place where they will not be damaged as a result of the blast or by subsequent vehicle movements.