Hazard and Risk

What is a Hazard?

When we refer to hazards in relation to occupational safety and health the most commonly used definition is ‘A Hazard is a potential source of harm or adverse health effect on a person or persons’.

The terms Hazard and Risk are often used interchangeably but this simple example explains the difference between the two.

If there was a spill of water in a room then that water would present a slipping hazard to persons passing through it. If access to that area was prevented by a physical barrier then the hazard would remain though the risk would be minimised.

What is Risk?

When we refer to risk in relation to occupational safety and health the most commonly used definition is ‘risk is the likelihood that a person may be harmed or suffers adverse health effects if exposed to a hazard.’

Categorising Risk

The level of risk is often categorised upon the potential harm or adverse health effect that the hazard may cause, the number of times persons are exposed and the number of persons exposed. For example exposure to airborne asbestos fibres will always be classified as high because a single exposure may cause potentially fatal lung disease, whereas the risk associated with using a display screen for a short period could be considered to be very low as the potential harm or adverse health effects are minimal.

What are Control Measures?

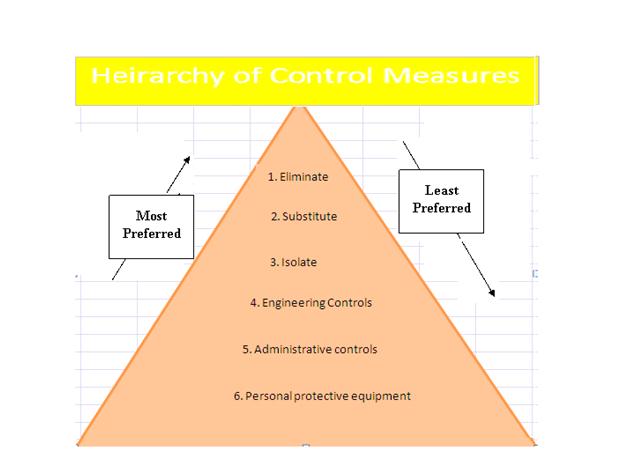

Control measures include actions that can be taken to reduce the potential of exposure to the hazard, or the control measure could be to remove the hazard or to reduce the likelihood of the risk of the exposure to that hazard being realised. A simple control measure would be the secure guarding of moving parts of machinery eliminating the potential for contact. When we look at control measures we often refer to the hierarchy of control measures.

| 1. Eliminate the hazard | Elimination of the hazard is not always achievable though it does totally remove the hazard and thereby eliminates the risk of exposure. An example of this would be that petrol station attendants in Ireland are no longer exposed to the risk of chronic lead poisoning following the removal of lead from petrol products sold at forecourts. |

| 2. Substitute the hazard with a lesser risk | Substituting the hazard may not remove all of the hazards associated with the process or activity and may introduce different hazards but the overall harm or health effects will be lessened. In laboratory research, toluene is now often used as a substitute for benzene. The solvent-properties of the two are similar but toluene is less toxic and is not categorised as a carcinogen although toluene can cause severe neurological harm. |

| 3. Isolate the hazard | Isolating the hazard is achieved by restricting access to plant and equipment or in the case of substances locking them away under strict controls. When using certain chemicals then a fume cupboard can isolate the hazard from the person, similarly placing noisy equipment in a non-accessible enclosure or room isolates the hazard from the person(s). |

| 4. Use engineering controls | Engineering Controls involve redesigning a process to place a barrier between the person and the hazard or remove the hazard from the person, such as machinery guarding, proximity guarding, extraction systems or removing the operator to a remote location away from the hazard. |

| 5. Use administrative controls | Administrative controls include adopting standard operating procedures or safe work practices or providing appropriate training, instruction or information to reduce the potential for harm and/or adverse health effects to person(s). Isolation and permit to work procedures are examples of administrative controls. |

| 6. Use personal protective equipment | Personal protective equipment (PPE) include gloves, glasses, earmuffs, aprons, safety footwear, dust masks which are designed to reduce exposure to the hazard. PPE is usually seen as the last line of defence and is usually used in conjunction with one or more of the other control measures. An example of the weakness of this control measure is that it is widely recognised that single-use dust masks cannot consistently achieve and maintain an effective facepiece-to-face seal, and cannot be adequately fit-tested and do not offer much, if any real protection against small particulates and may lead to a false sense of security and increase risk. In such instances an extraction system with fitted respirators may be preferable where the hazard may have significant health effects from low levels of exposure such as using isocyante containing chemicals. |

What is Risk Assessment?

Risk Assessment is where the severity of the Hazard and its potential outcomes are considered in conjunction with other factors including the level of exposure and the numbers of persons exposed and the risk of that hazard being realised. There are a number of different formulae used to calculate the overall risk from basic calculations using high, medium and low categories to complicated algorithms to calculate risks at Nuclear power stations and other high risk work locations.

It is important to ensure that the residual risk following implementation of control measures is ‘as low as is reasonably possible (ALARP). For a risk to be ALARP it must be possible to demonstrate that the cost involved in reducing the risk further would be grossly disproportionate to the benefit gained. Further guidance on risk assessment can be found in the publication Guidelines on Risk Assessments (2.1 Mb) .