Whole-Body Vibration in Quarries

|

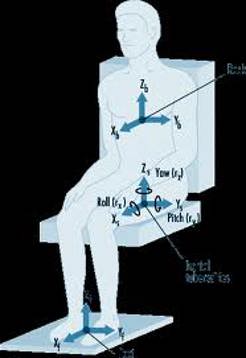

Whole-body vibration (WBV) is the vibration and shock felt when sitting or standing on a vehicle or machine, travelling over rough ground or along a track, or the vibration when working near powerful machinery such as a rock crusher. Shocks can occur, for example, when driving over bumps or potholes. Exposure to WBV at low levels is unlikely on its own to cause back injury, but it can aggravate existing back injuries which may cause pain. Low back pain has been shown to be the leading major cause of industrial disability in the population under the age of 45 years and has been linked to whole body vibration exposure Action to reduce workplace exposure to WBV is required for most mobile quarrying machinery. Machinery that can expose workers to WBV is identified below:

|

|

Controls to reduce the risk of WBV

| Precautionary measures | Selecting suitable machinery | Construction and maintenance of haul roads |

|

Establish who is responsible for managing the control of risk from exposure to WBV or shock. Find out what can reduce shock, such as adequate maintenance of tracks. Find out what can reduce vibration, such as limiting speed or good maintenance of machinery suspensions. Find out vibration information when purchasing or hiring machinery. Provide information and training for operators on how to minimise exposure to WBV and shock and how to recognise and report symptoms |

Is the equipment suitable for the intended task? Is the equipment properly maintained in accordance with the manufacturer’s recommendations? Will the machinery cause unnecessary vibration exposure? Did you supply machinery with low vibration emissions? Did the supplier inform you of the WBV emission level? Did the supplier provide additional information about WBV, as necessary, for the machinery to be used safely. |

Construct and maintain roadways, stock areas and other vehicle manoeuvring areas to a high standard, according to the machinery that will use them. Where there are permanent roadways in the quarry, consider constructing these roads to highways standard. Repair potholes to avoid shocks. Design and maintain roads to be even to avoid poor posture, high vibration and shock, particularly in articulated dumpers. Design road cambers to avoid or minimise poor posture. Construct roadways with good drainage to help reduce deterioration. |

Using under-sized or under-powered machinery is likely to increase exposure to WBV and shock. It may be possible to reorganise the extraction process to minimise the use of mobile plant.

Grading of roadways has sometimes been reported to be a cause of high exposure to WBV. The schedule for road maintenance should balance the exposures of haul truck operators with those of grader operators.

Job rotation should only be used to reduce exposure to shocks after other measures have been put in place to minimise shock as job rotation may increase the number of operators at risk if large shocks are present.

Maintenance and adjustment of seats

Machine manufacturers/suppliers must ensure that the seat adjustment controls are readily accessible and easy to use. The same applies to the retrofitting of replacement seats.

operators should be trained to set seats correctly. Incorrect seat adjustment is frequently the source of poor posture and unnecessary vibration or shock.

Check, lubricate and maintain seat, cab and chassis suspensions in accordance with the manufacturer’s instructions.

Training

A competent and skilled machine operator who drives in a smooth and controlled manner will often generate lower exposure to vibration than a less skilled operator or someone working under pressure.

It is important to train machine operators and give them information about:

- the risks of lower back pain in their jobs;

- the factors that are within their control (such as

- choice of speed and route) and where experience has shown these to be important;

- how to set the seat for good posture and to set the suspension correctly to minimise vibration;

- how to locate and adjust convex mirrors and CCTV so that they can use them without twisting and stretching; and

- how to identify and report faults.