Safe Alert for Large Tyre Inflation

A series of fatal accidents involving large tyre inflation in 2014 has prompted the Health and Safety Authority to issue this safety alert to highlight the need for safe procedures during large tyre inflation in all work sectors.

This safety alert deals with the dangers associated with large tyre inflation

Dangers of explosive energy stored in tyres

Inflated tyres contain a large amount of stored energy. For example, the sidewall of a typical commercial vehicle (CV) tyre typically has over 34 tonnes of force acting on it.

Tyres are designed to withstand this but if they are damaged or used while flat [run flat], or significantly underinflated, they may fail.

The force can then be released explosively and result in a destructive air blast and the ejection of high-speed particles. These types of tyre explosion have led to numerous deaths at work

Risk of failure

Removal, replacement and inflation of tyres is an extremely common practice, so it may seem a simple task. But it can cause very serious injury and death from:

explosion of the tyre or disintegration of the wheel during inflation

manual handling of the tyre and wheel

collapse of an elevated vehicle

Cuts and splits should be clearly visible by inspection and there are industry standards on whether a repair should be attempted.

However, damage to the internal steel or textile cords may not be obvious.

This internal damage may not become obvious until the tyre is reinflated and a bulge occurs. At this stage, the additional strain placed on the adjacent cords can cause them to break in rapid succession, until the casing splits apart violently. This is commonly known as a ‘zipper-failure’

To reduce the risk of violent explosion

Before deflating a tyre, check the pressure and chalk the reading on the tyre wall. Remember, low tyre pressure may have caused tyre wall damage.

Do not inflate any tyre that has been significantly underinflated until it has been adequately checked. Examine wheels and tyres (externally and internally) for signs of damage, such as cracks, ‘marbling’ (black lines), bulging, soft spots or exposed steel cord in the tyre carcass. If in doubt, DO NOT re-inflate the tyre.

- Do not use airlines without either a functioning pressure gauge or pressure control device being fitted.

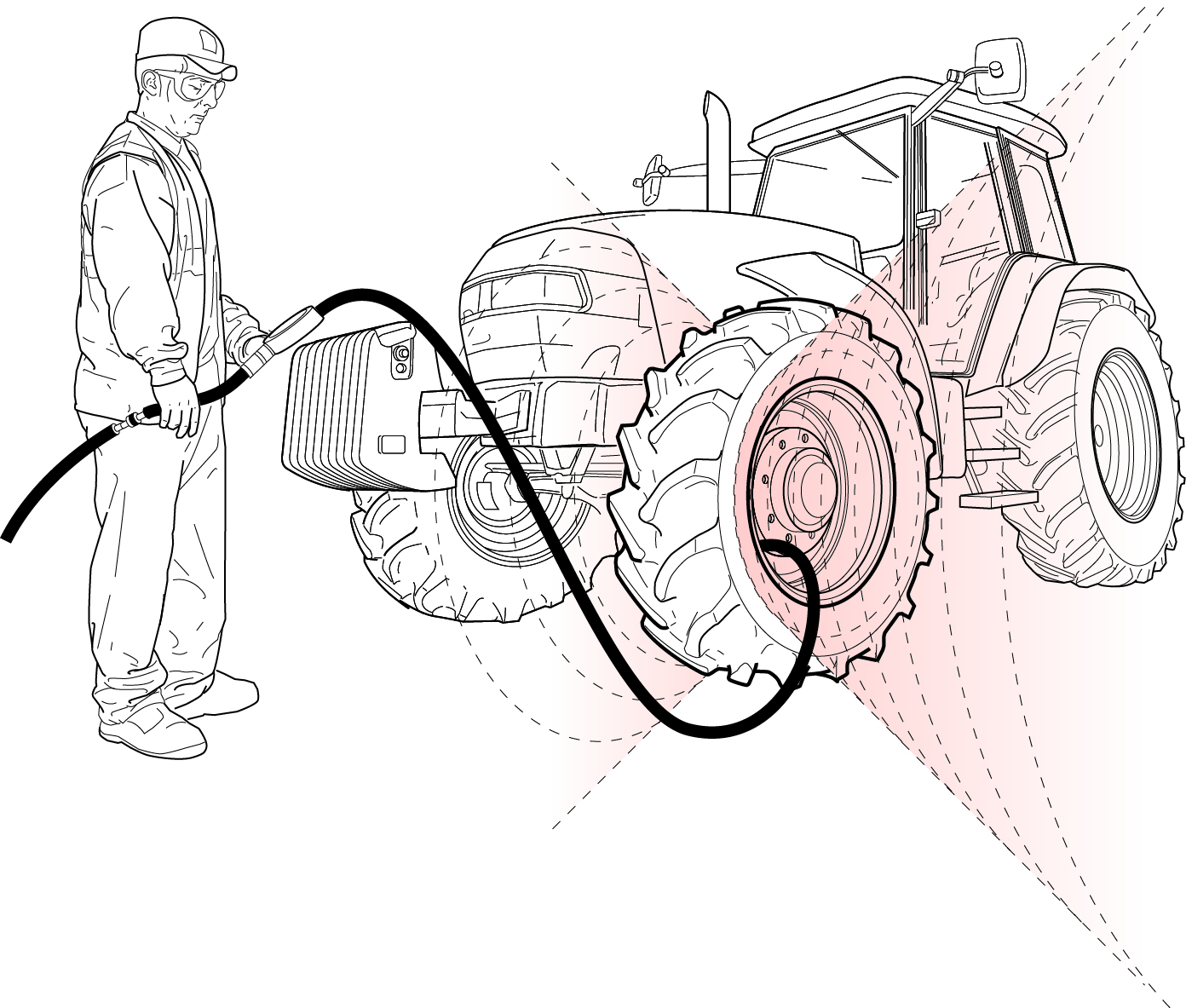

Stay outside the likely explosion trajectory, when reinflating a tyre.

Watch and listen for signs that might indicate a zipper failure. If you suspect a problem, do not approach the tyre to deflate it – use the quick-release connection at the operator’s end of the hose.

Figure 1 Tyre Explosion trajectory and safe position for inflation

Training of workers in tyre maintenance

Workers involved in tyre servicing, repair and maintenance, should undergo appropriate instruction and training before they start work. which must include the following elements as a minimum:

How to check tyre inflation equipment and tools before work starts to make sure they are in a safe working condition.

How to properly demount tyres, including proper deflation.

How to inspect rim/wheel components for mismatch and damage. Typical damage includes corrosion and rust build up, metal cracks, deformed flanges, sprung side and/or lock rings, broken or cracked discs, damaged rim bases, worn tubes or flaps and bent or broken beads in the tyres.

How to mount tyres properly to rims/ wheels. This means the proper procedure to follow, the proper tools and safety equipment to use, the assembly inspections to make and the inflation steps to take.

How to use restraining devices properly.

How to handle tyre assemblies and rims/wheels properly. This may include the use of mechanical aids in the handling of heavy tyre assemblies.

How to install and remove tyre assemblies.

How to inflate tyres mounted on the vehicle

Personal Protective equipment [PPE] for tyre inflation

To avoid unnecessary injury to body and eyes, the following personal protective equipment must be used, as a minimum, when servicing tyres,

Tyres on commercial vehicles and very large tyres

Extra safety measures are needed for inflating larger, well-based (single-piece) tyres above 15 psi. This includes some light tyres which are inflated to around 70 psi and may cause serious injury in the event of failure.

The extra measures include using a restraining device such as:

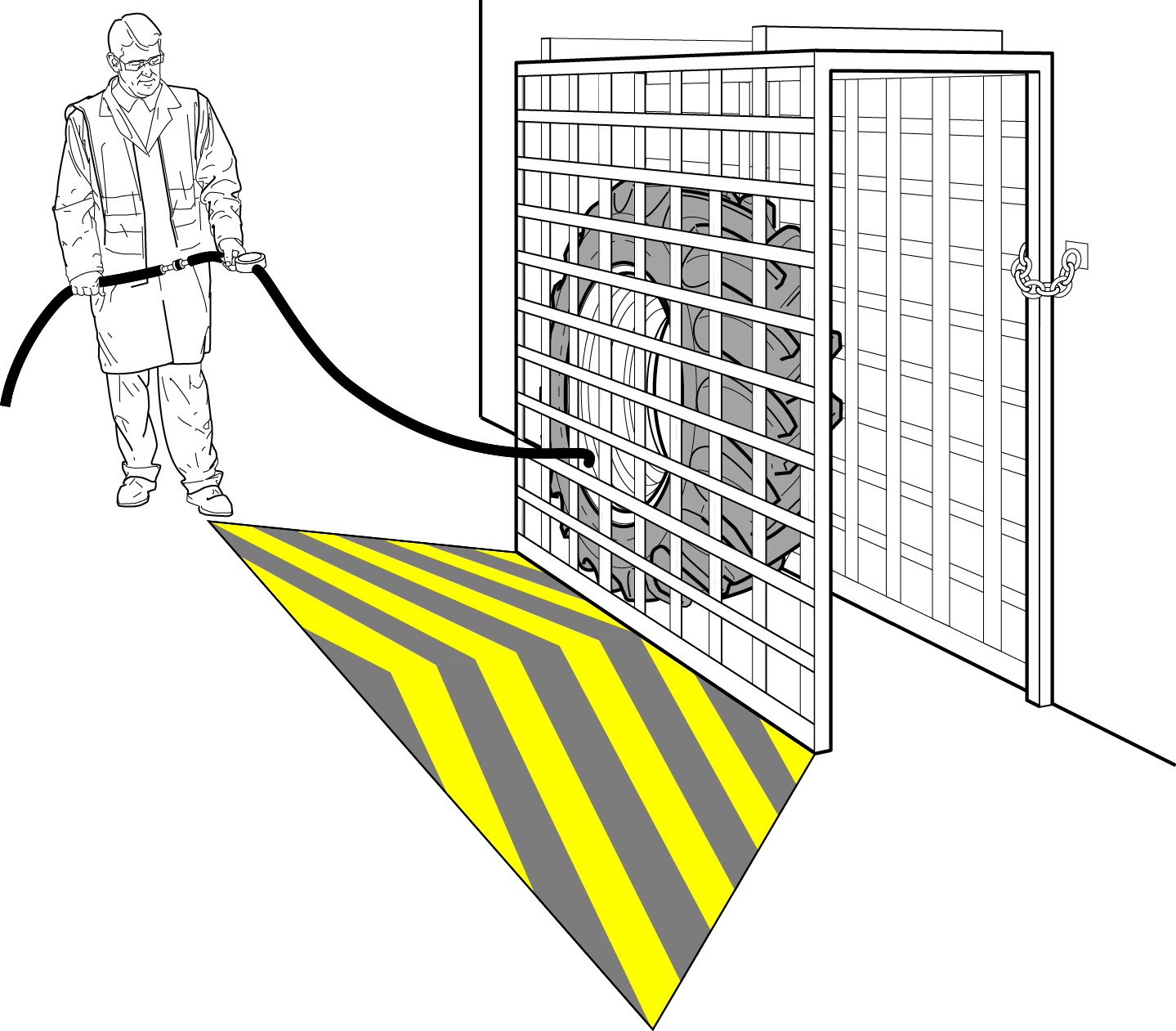

a strong, firmly-secured tyre inflation cage. Consider lining this with mesh to retain debris. For fixed installations, it is helpful to mark the safety exclusion zone on the workshop floor as a reminder to staff. See Figure 2

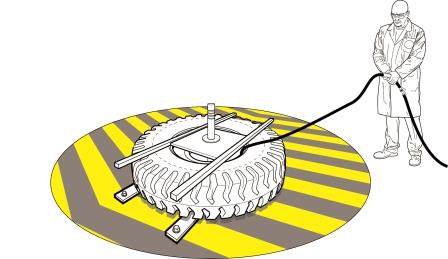

a secured horizontal stool and associated clamping mechanism. See Figure 3

a portable restraint. Examples include a lightweight cover that encloses the tyre and wheel rim. This may be particularly useful for off-site repairs. In the event of an explosion the fabric contains projected debris. Fabric devices may need to be replaced after an explosion.

Very large tyres found on vehicles used in construction, quarries and agriculture pose additional hazards during fitting and inflation due to their size and weight.

It may not be reasonably practicable to provide purpose-built cages of adequate strength, particularly for work on site.

Effective tyre restraint during inflation can be achieved by:

mounting on the wheel hub of the vehicle

using a protective barrier, such as a wall, embankment or the side of another vehicle, to restrain flying objects ejected during a failure

Keeping all people in a safe position outside the likely explosion trajectory [Any potential path or route that a rim/wheel component may travel during an explosive separation, or the sudden release of pressurised air]. It is helpful to put a suitable barrier in place to prevent persons entering the work area.

Figure 2. A strong firmly secured cage used to restrain large tyre during inflation operation. Also consider lning this cage with mesh to catch any flying debris.Long connection hose enables worker to stand in safe position.

Figure 3. A secured horizontal stool and clamping mechanism for safe inflation. Long hoses enable worker to stand in safe position away from potential explosion trajectory.

'Images used by permission of the Health and Safety Executive, UK'

For more detailed information, including videos go to:

http://www.hsa.ie/eng/Your_Industry/Quarrying/Maintenance_Operations/Tyre_Changing_and_Repair/

http://www.hse.gov.uk/pubns/indg433.pdf.

May 2015