Machinery

- Machinery Fatalities

- Precautions

- Guarding

- Lifting Equipment

- Maintenance of Machinery

- Workshop

- Machinery Checks

Machinery Fatalities

Tractors and Machinery are the main cause of farm accidents in Ireland. Elderly farmers and children are at particular risk. Being entangled in PTO’s, crushed under a machine part, caught in a machine mechanism, crushed between vehicles and struck by a machine object are the main causes of deaths with farm machinery.

Keys to prevention are training, good maintenance and safe work practices.

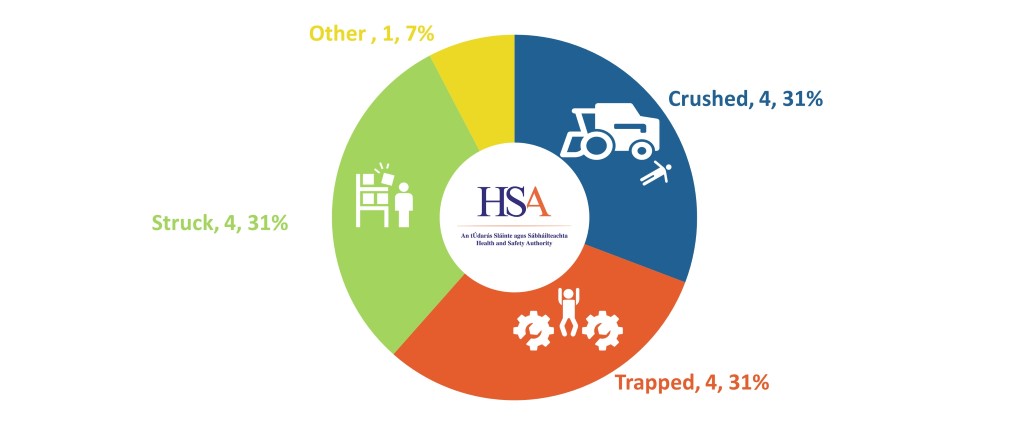

Work-related fatalities involving machinery 2014 -2023 (total machinery fatalities 13)

Precautions

|

|

- Suitable guards should be fitted to all machinery and equipment

- Always use axle stands or wooden blocks to support raised machinery. Jacks are only for lifting not supporting

- All tools and equipment should be in good working order with suitable safety devices in place

- Hydraulic equipment should be supported with an adequate prop during maintenance or repair (e.g. jack stands)

- The PTO and moving parts should be stopped before attempting to free any machine blockage

- Passengers should not be carried on machines unless designed to do so

- Loads should be stable and well secured

- Operate the equipment from the correct position. Never get into a 'trap zone'

- Loose or torn clothing should not be worn when you are working near machinery. It is best to wear well-fitting overalls with zipped pockets and safety boots with steel toe-caps

Guarding

|

|

Power take-off (PTO) guarding

In this video, Peter talks about and shows the injuries received from an unguarded PTO shaft.

Viewer discretion is advised.

In this video, Brian and Patrick Phelan discuss Brian's PTO accident and his injuries.

In this video, farmer John Goff recalls how he lost his arm in a PTO shaft accident.

|

|

- While all PTO guards should be in place, particular priority should be given to PTOs used in stationary situations (including slurry tankers and grain rollers)

Lifting Equipment

|

|

- It is a legal requirement to have Lifting Equipment examined by a competent person

- at 12 month intervals if used to lift materials

- at 6 month intervals if lifting accessories for lifting materials such as slings, hooks or equipment used to lift people

- Fixed lifting equipment must be tested as part of a thorough examination before being used for the first time

- All lifting equipment must be tested after any substantial alteration or repair

- Hydraulically - operated machines used to lift more than 1,000 Kg should be fitted with check valves or some other suitable device to prevent collapse

Maintenance of machinery

In this video, Sean talks about and shows the injuries received when a combine harvester fell on him (5 minutes, 10 seconds)

|

|

Workshop

- Consider having repairs done by a competent mechanic

|

|

- Before use, make sure that the power tool is in a safe operating condition, with all the guards in place. Clamp the piece being worked on with a vice

- With angle grinders, make sure the correct disc is being used and is properly fitted. Never force the disc at the metal, or allow the disc to be trapped in the work piece

- Welding requires skill, so get training

- Air compressors can explode if not maintained

- An inspection by a competent person is required every 24 months

- Always use a high-quality pressure gauge to make sure that a tyre is inflated to the correct pressure

- When inflating a tyre fitted to a split rim, always use a safety cage or an airline extension

- Suitable clothing includes well-fitting overalls with zipped pockets, leather footwear with non- slip soles and steel toe boots

|

|

Machinery Checks

- All safety guards/ devices fitted

- The PTO "O" guards present

- Hydraulic systems and hoses in good repair

- All machinery defects identified and corrected

- Regular maintenance carried out