Asphalt Plant Safety

|

At Asphalt Plants there are hazards resulting from

Detailed information from Wirtgen showing the Operation of Asphalt Plants is available here Detailed information about identifying and managing the risks at Asphalt Plants prepared buy SIAC Bituminous Products is available here Detailed information from Atlantic about bitumen, controlled unloading and control measures is available here The simplified process is shown below |

|

Simplified Basic Process of Making Asphalt

Bitumen is stored in one or more tanks and is kept at a temperature in excess of 1500 Centigrade and transported into the Asphalt process through a pipeline

Raw materials are held in hoppers or storage bins which are transported by conveyor into a dryer

The raw materials are dried in a dryer which operates at about 1800 Centigrade

The Drying Process can be seen in this video supplied by Wirtgen Group

The removed moisture and particles is scrubbed and filtered before being released into the atmosphere. The filtered material is often reused as filler.

The operation of the Filter can be seen in this video supplied by Wirtgen Group

The dried material is taken to a screening area where it is stored according to its size and fed into the mixer

|

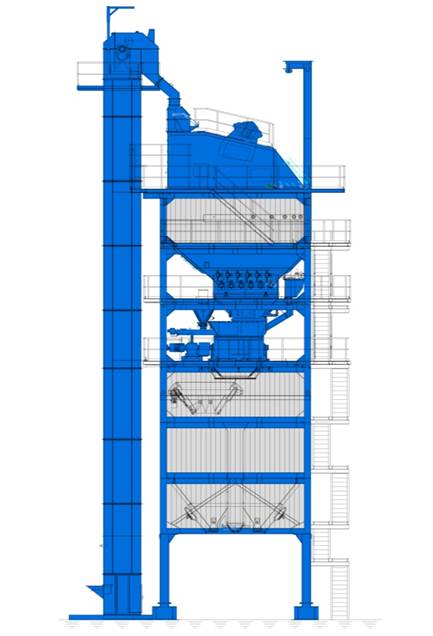

Hot Screening Bin |

Mixing Tower |

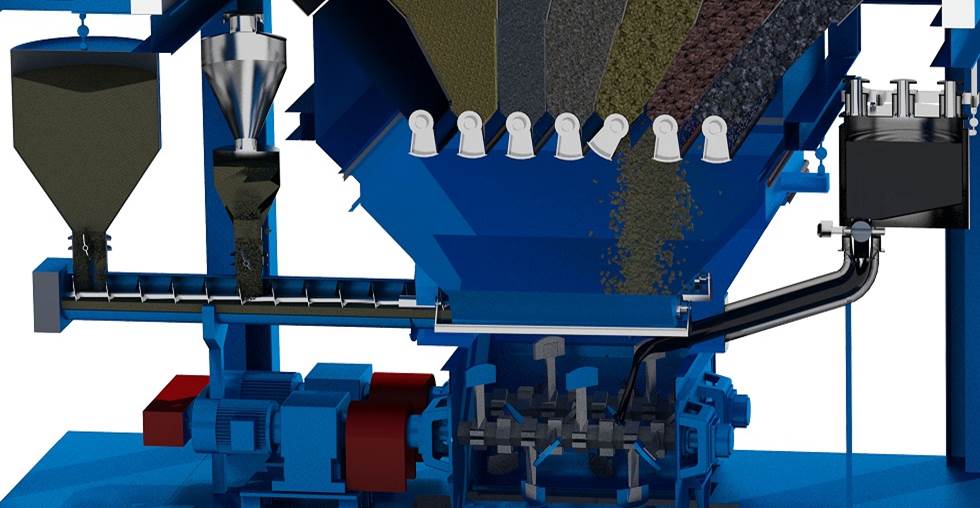

The material is then fed into a mixer where hot bitumen is added and vigorously mixed. Other materials such as filler may be added in this process

The operation of the Mixer can be seen in this video supplied by Wirtgen Group

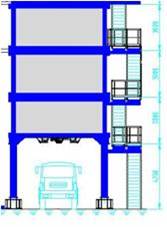

The Asphalt is loaded into a skip and either loaded directly into a vehicle or into a storage bin and then into a vehicle

|

|

|

The truck, which has an insulated body, carrying the asphalt is then covered before leaving the site