Reducing Errors and Non-Compliances

We can all make errors and break rules no matter how well trained, experienced and motivated we are to do something right. The challenge is to develop systems to prevent errors and non-compliances initiating an accident. They should be managed proactively as part of the risk assessment.

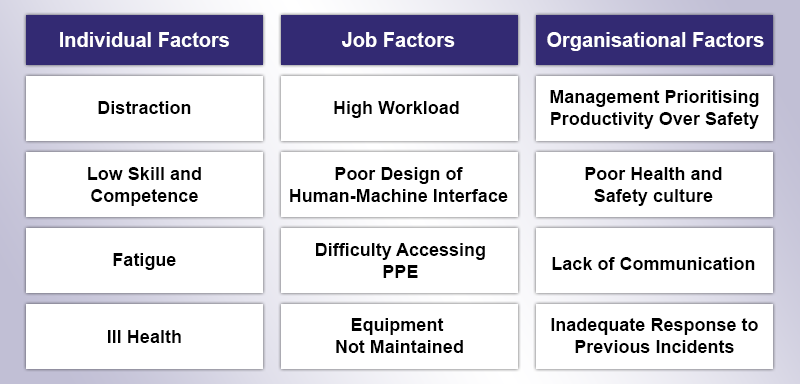

What makes errors and non-compliances more likely?

Many factors can make errors and non-compliances more likely and these can be categorised as individual, job and organisational factors. The table below shows examples of factors that can increase the likelihood of errors and non-compliances.

Consider the factors, fatigue, human-machine interface design and safety critical communication and how these factors might combine to increase the likelihood of error. For example, consider how the decisions and actions of operators working on a safety critical task in a control room may be influenced by fatigue, poor design and inadequate communication:

- Fatigue can mean that operators have slower reactions times, are compromised in their perception of risk or lose focus.

- Poor design of the human-machine interface can mean that operators are working with a display screen with no easy access to critical information (e.g. it is not in their normal field of view).

- Inadequate safety critical communication can mean that operators have not received critical information at shift handover.

This combination of factors means that such operators are more likely to make errors that can lead to an accident.

How can errors and non-compliances be reduced?

Understanding the different categories of errors and non-compliances that show up in the workplace can help identify ways of reducing them. The tables below show three different categories - skill-based errors, mistakes and non-compliances.

Skill-based errors – slips and lapses

Slips and lapses occur on tasks that are very routine tasks. They happen when we don’t have to think much about the task in order to do it (e.g. driving), sometimes described as being on ‘auto-pilot’. They occur because we get distracted, interrupted or our attention is diverted. One way they can be reduced is with human-centred design e.g. standardising the design of controls.

|

Types of skill-based error |

Examples |

Reducing skill-based errors |

|

Slips – a simple frequently performed action goes wrong |

Move a switch up rather than down (wrong action on right object) |

|

|

Lapses – a short term memory lapse, omit to perform a required action |

Forget to indicate at a road junction |

Table adapted from the Health and Safety Executive UK

Mistakes

Mistakes are a more complex type of human error where a person does the wrong thing believing it to be right – we make a poor judgement. See the table below for ways to reduce mistakes.

|

Types of Mistakes |

Examples

|

Reducing mistakes |

|

Rule-based mistake – misapply a good rule or apply a bad rule |

Misjudge overtaking manoeuvre in unfamiliar, under-powered car |

|

|

Knowledge-based mistake – novel situation where there are no rules but insufficient knowledge |

Misdiagnose a process upset due to lack of experience and knowledge |

Table adapted from the Health and Safety Executive UK

Non-compliances

Non-compliances are very common in our work and our everyday lives. There is a tendency to think that non-compliances are what ‘other people’ do. Non-compliances are deliberate deviations from rules, procedures, instructions and regulations and are mostly motivated by a desire to complete the task.

|

Types of Non-Compliances |

Examples |

Reducing Non-Compliances |

|

Routine – breaking a rule has become a normal way of working |

Driving beyond the speed limit |

|

|

Situational – breaking a rule due to job pressures |

Not wearing PPE because it’s uncomfortable in ‘this situation’ |

|

|

Exceptional – happen in emergency situations where there is a belief that breaking rule is more beneficial |

Captain Sully landing a plane in the Hudson river |

Table adapted from the Health and Safety Executive UK

In some cases it can be difficult to place an error or non-compliance in a single category. There may be a combination of underlying causes requiring a combination of preventative measures.